A Gemstone's Journey: 4. Cutting & Polishing

Share

Gemstones are naturally occurring minerals that are valued for their beauty and rarity. Once a gemstone is mined, it goes through several processes to bring out its inherent beauty. The journey of a gemstone from mine to jewelry involves several stages, including cutting and polishing. In this blog post, we will discuss the cutting and polishing process for gemstones.

Cutting Process:

The cutting process is an essential step in bringing out the brilliance and beauty of a gemstone. It involves shaping a rough gemstone into a semi-finished product with a general overall shape and a few facets, this is called the pre-form. The cutting process is carried out by skilled craftsmen known as lapidaries, who use specialized tools to create intricate shapes and designs.

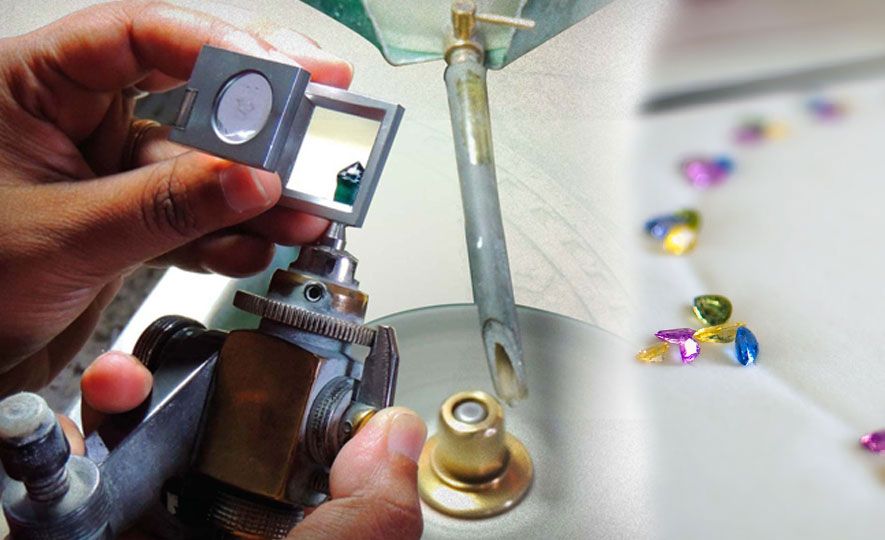

The first step in the cutting process is to examine the rough gemstone to determine its shape and size. Lapidaries will often use a loupe, a small magnifying glass, to examine the stone's internal structure to determine the best way to cut it. They will also take into consideration the stone's color and clarity, as these factors can affect the finished product's value.

Once the lapidary has determined the best way to cut the gemstone, they will use a diamond saw to cut the stone into a rough shape. The lapidary will then use a faceting machine to cut and polish the stone's facets. The faceting machine is a precision instrument that holds the stone in place while the lapidary uses a series of diamond-coated wheels to shape and polish the facets.

Polishing Process:

The polishing process is the final step in bringing out the brilliance and beauty of a gemstone. Once the stone has been cut into its final shape, it is polished to create a smooth, reflective surface. Polishing is done using a series of polishing wheels, each with a progressively finer abrasive material.

The lapidary will begin the polishing process using a coarse abrasive material, such as diamond powder or aluminum oxide. The lapidary will then move on to progressively finer abrasive materials until the stone has a mirror-like finish. The final step in the polishing process is to clean the stone with soap and water and dry it thoroughly.

Evolution of Cutting and Polishing Process:

The art of cutting and polishing gemstones has evolved over time, with new technologies and techniques being developed to improve the process's precision and efficiency. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies has revolutionized the cutting and polishing process, allowing lapidaries to create intricate designs with unparalleled accuracy and precision.

In addition to new technologies, lapidaries have also developed new cutting and polishing techniques to bring out the best in each gemstone. For example, the Portuguese cut is a cutting technique that was developed in the 18th century and is still used today for sapphires and other gemstones. This cut involves cutting the stone into a round shape with a large number of facets to maximize its brilliance and sparkle.

The cutting and polishing process is an essential step in bringing out the inherent beauty of a gemstone. With the evolution of new technologies and techniques, lapidaries can create intricate designs with unparalleled accuracy and precision. Understanding the cutting and polishing process can help you appreciate the skill and craftsmanship that goes into creating a beautiful piece of jewelry.